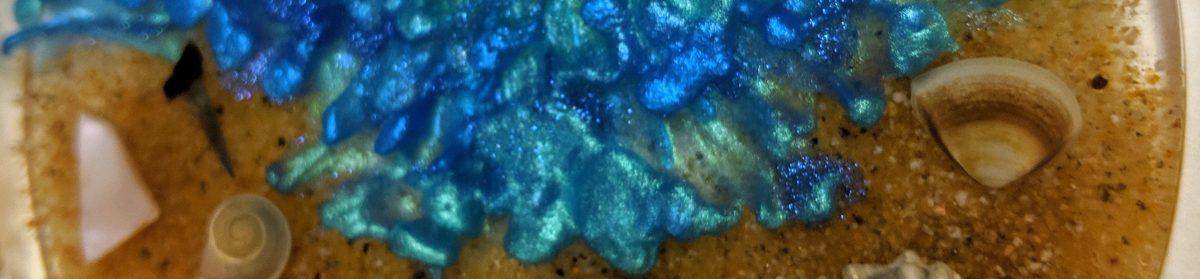

I signed up for a space at a local farmer’s market for the months of September and October, so I have been trying to build up an inventory of small things (smaller glass pieces and coasters) to sell in addition to my stained glass in recycled windows. I also bought some various blue glass materials to use for the water in the beach coasters. I decided to try three different types of glass for this round of coasters. I really love the look of the “Blue Shells” glass, so I used that for some. Additionally, I used some fairy garden glass chips and another shade of larger (but still tiny) fairy glass globs.

Below is how the fairy glass globs looked when set in the resin.

I poured all of these coasters in two layers, one day apart. Since I learned that the type of resin I’m using is meant for thin applications, I went back to my old layering method of pouring. The demolding revealed another anomaly in the resin, however. The coasters with the fairy glass chips warped when they cured, so the tops of all four of them were uneven.

All the other coasters turned out to be fine, only the ones using that particular glass warped. They will obviously not be particularly useful as coasters with the tops so warped. After further inspection, I realized that one of the new molds I just purchased for coasters is defective, causing the warping. Unfortunately I wasted a lot of materials before I realized why the warping was occurring.

Another lesson learned. Luckily my new resins arrived today, so I can start using the proper resin for thicker molds going forward. The type I normally use is good for thin coatings only. I must just be fortunate that my previous coaster creations turned out fine using it!