Glass of Sherry

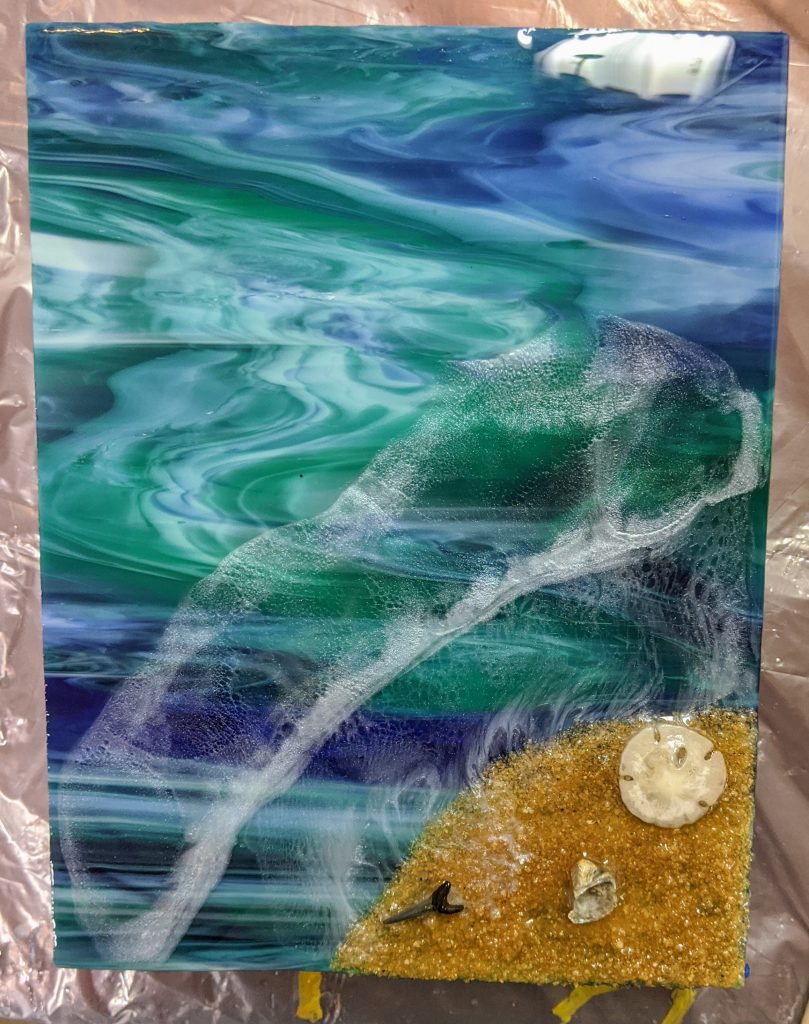

Today I added the last wave to my second beach glass panel, made another Palmetto and Crescent glass panel, finished a second metallic flake coaster and started a brand new cast resin bracelet project.

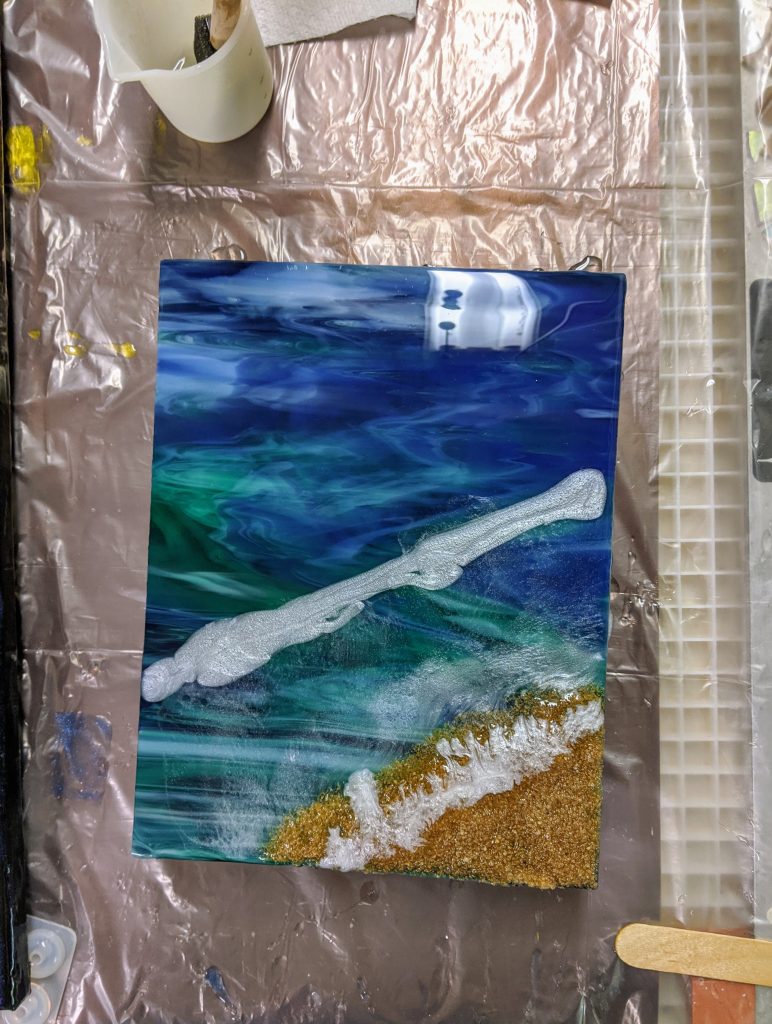

First I mixed up 80 ml of resin and set aside about a tbsp for the white wave for the beach panel. I spread the resin over the desired areas of the panels and mixed the white portion for the bubbles of the waves. I used the heat gun to manipulate the resin coating and also to remove bubbles. Next it was time to add the white bubble detail to the beach waves. I also got a new bangle bracelet mold and decided to use some of the extra resin for that. I should have waited until I had some mold release (this mold is hard plastic, not silicone like I’m used to), but I decided that I could try it out without the release for experience’s sake.

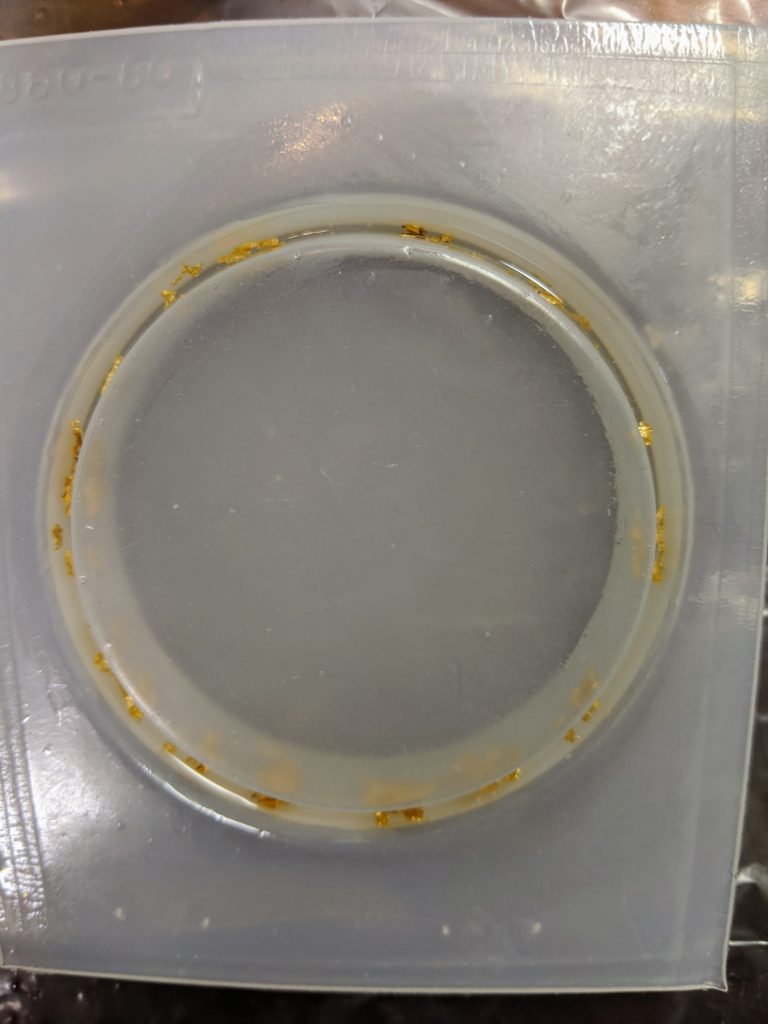

I couldn’t resist trying out a new bangle bracelet mold I ordered. I thought it was silicone, but it is hard plastic. I ordered some mold release for it, but this is an experiment to see how much I need the release chemical.

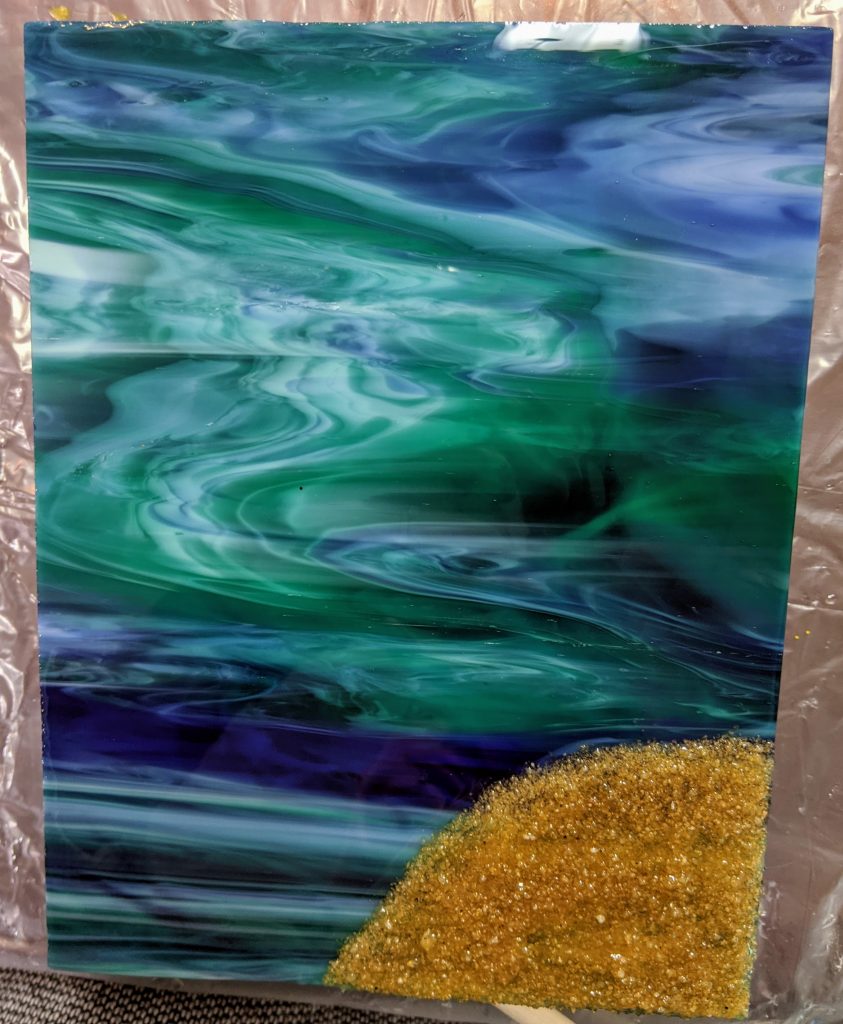

I also added some glass chips to an orange and white Palmetto and Crescent glass panel. The chips add some nice sparkle!

The bangle bracelet still needs a bit more resin, and it will take some practice to figure out how to place the decorations / pigments in that mold, so check back!

So doing the wave layers just takes a short amount of time (maybe an hour total including setup and cleanup) each day, but here is today’s progress. First I mixed 80 ml of resin, setting aside a very small amount (about 1 TBSP) for the white pigment for the wave bubbles. I then spread the resin over most of the glass, leaving out most of the part where the sand and the first white bubbles are located. I then used the heat gun to remove bubbles and added a line of white resin all along the very edge of the clear resin.

Next I used the heat gun to spread the white pigment and then the torch to add detail to the bubbles.

I also had some touch up to do on the Palmetto and Crescent panel, as I added glass chips late last night and sprayed over them with resin spray and I wasn’t happy with the look. Soooo I spread another layer of clear resin over the panel and added the chips again. I also used the leftover clear resin to finish up one of the coasters from yesterday, so tomorrow I should be able to see how it looks. 🙂 I will also add at least one more wave to the beach panel (hopefully also tomorrow).

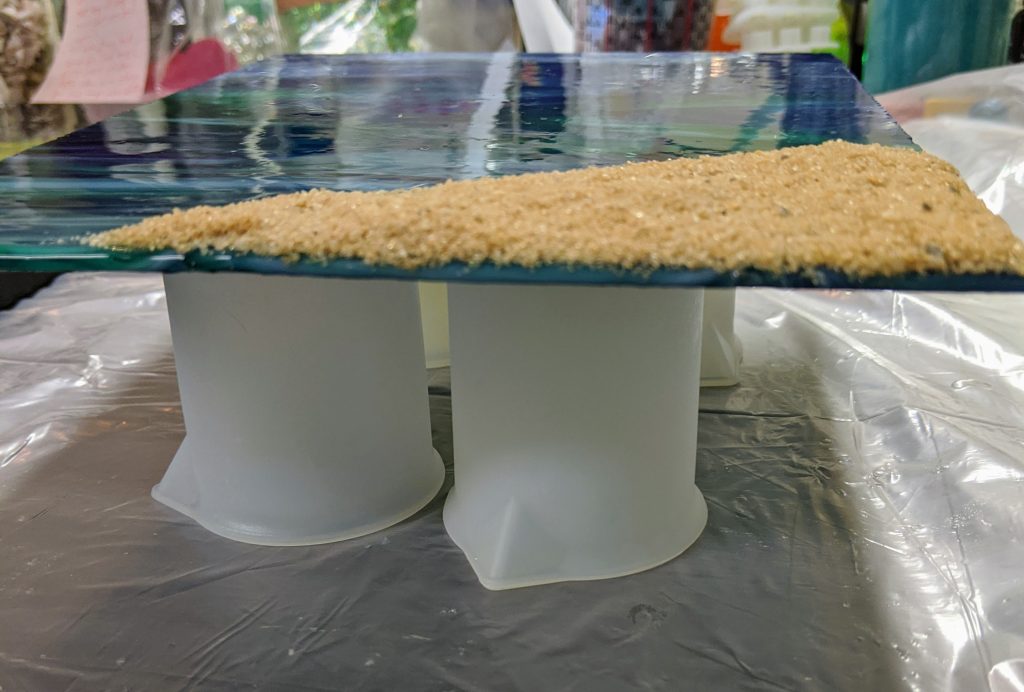

So yesterday I planned to work on these, but my real job was too busy, so today was the day. I added the first wave layer to my second beach / waves over stained glass panel, poured the resin coating on my stained glass “Clemson” colors Palmetto and Crescent panel, and added the second layer to my two alcohol ink / gold flake resin coasters.

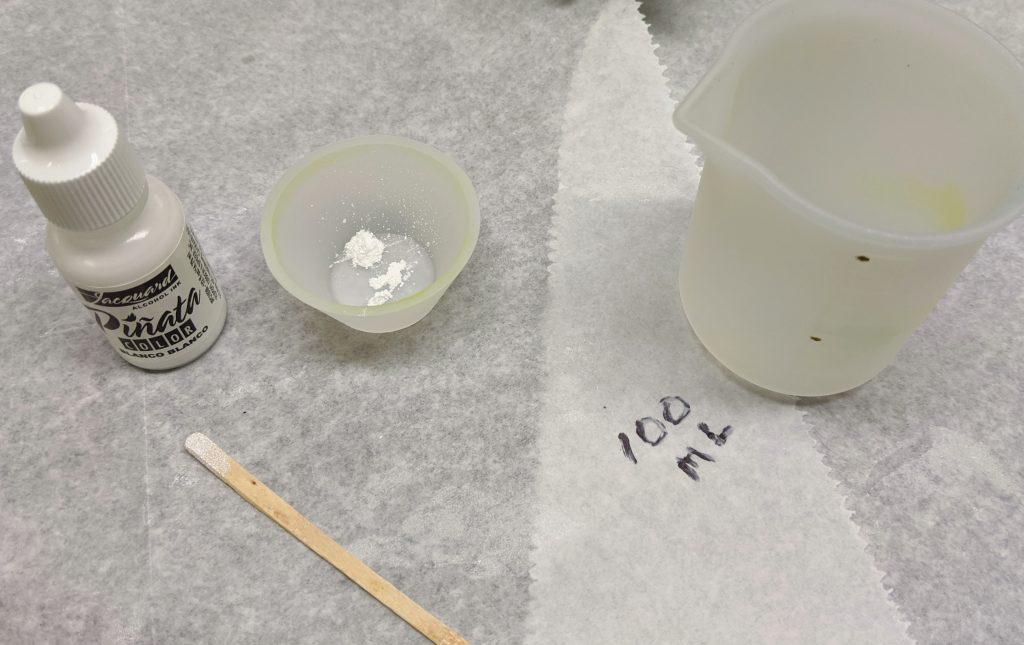

I mixed 100 ml of resin, then set a small amount aside for the white part of the waves on my beach panel. Next I poured the clear layer of resin over the glass panels and spread the resin around with a sponge on a stick.

Once the resin was spread all over the base glass, I used my heat gun to remove bubbles and spread the resin a bit more evenly. Next, I added a line of white tinted resin (powdered pigment plus a drop of white alcohol ink) to the sandy beach part of the wave panel.

Next I used my craft torch to spread out the white bubbles of the wave. The alcohol ink drop helps create the feathery effect in the resin when the torch hits it. I really only wave the torch very briefly over the white resin one time. The torch can quickly crack the stained glass if it gets too hot.

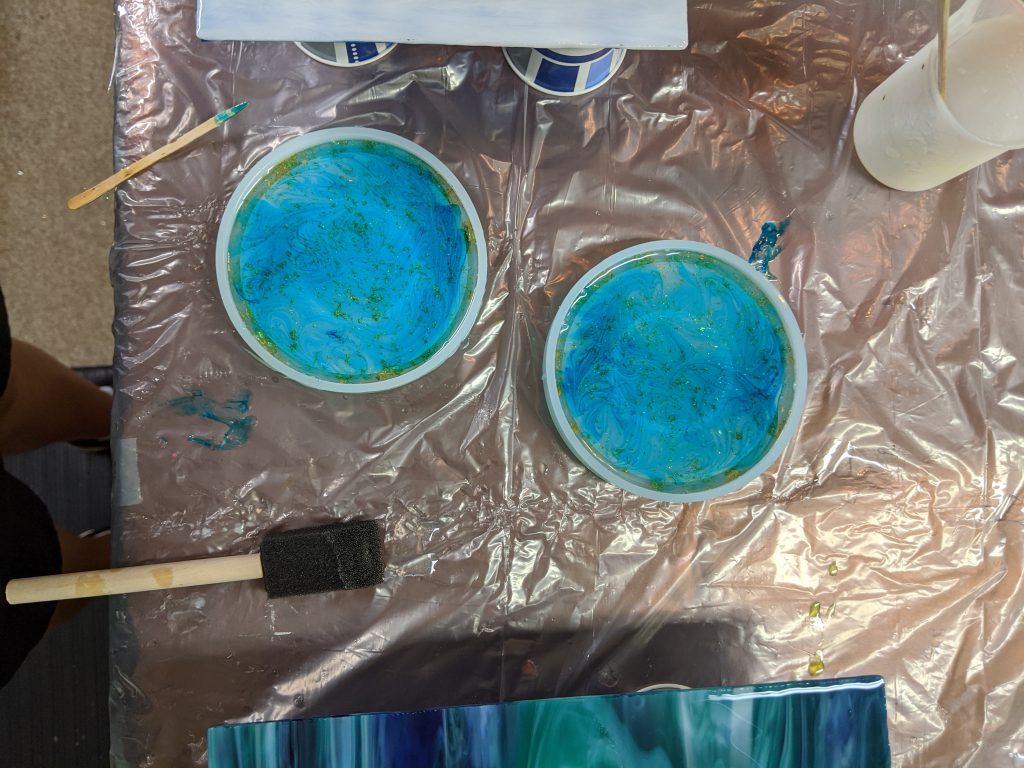

Next I poured the leftover clear resin into the coaster molds I started two days ago. The first layer was clear with some metallic flakes and a drop of blue alcohol ink. This layer was clear with about three drops of blue ink, which I added directly into the clear resin after I poured it into the molds. Afterward, I blew it with my heat gun (obligatory bubble removal) and manipulated a bit with a small craft stick.

I will likely need to add another layer of clear resin to the coasters and I’m hoping to add two more layers of wave to the beach panel, but the palmetto and crescent panel should be all set tomorrow afternoon. I will probably also brush a very light coat of resin over the sand dollar, shark tooth and shell on the beach panel.

Today I started another layered wave over glass project. I need more practice to get the layers the way I want to see them. I also decided to make a “Clemson” version of the palmetto and crescent. My leftover resin went to a new coaster project where I’m trying out a new “beachy look” theme with metallic flakes and some blue alcohol ink.

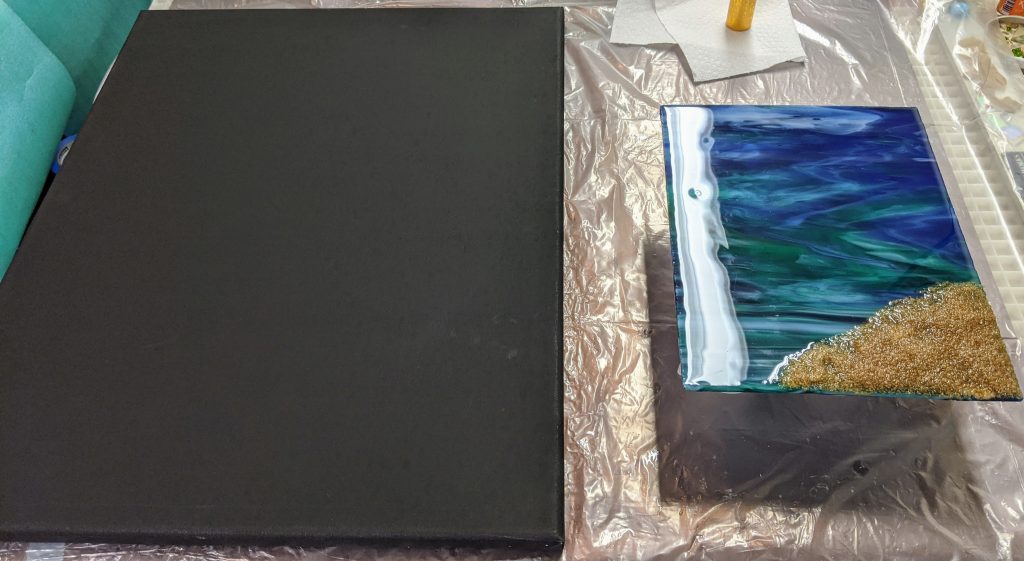

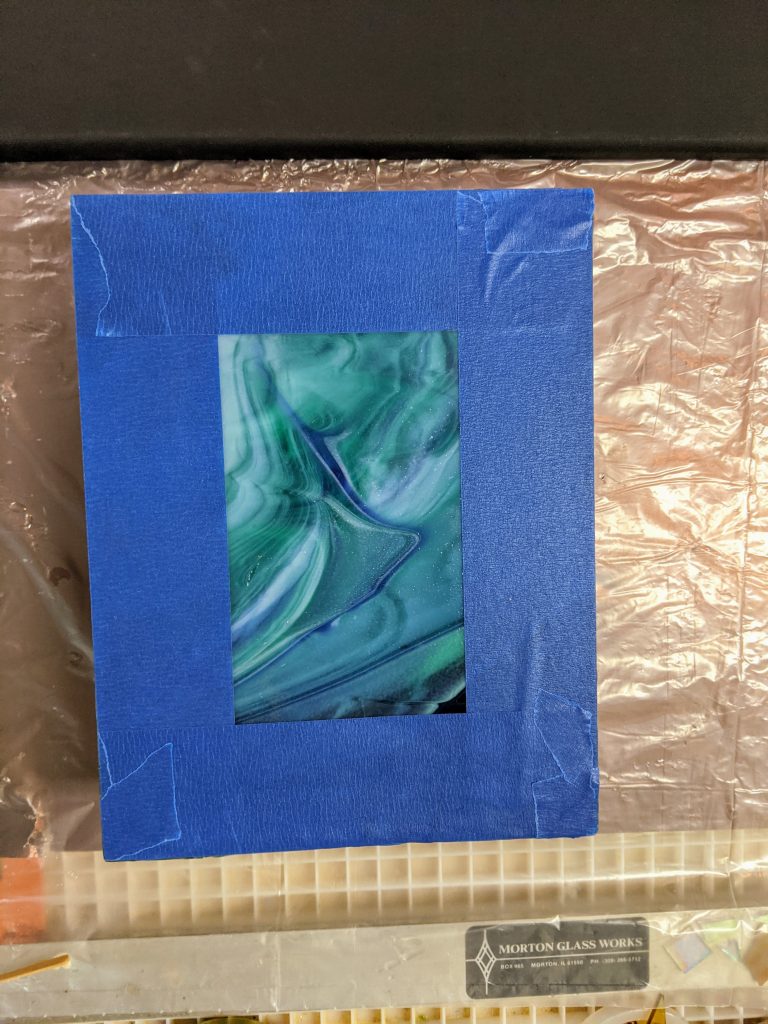

My first resin wave layers over glass project looked great, but I felt like I made the sand layer too thick, so for the past couple of days I have been slowly layering the sand to the point where it is pretty much opaque, but not thick. My plan for today was to pour the first layer of clear resin. I also wanted to add the first wave (white pigment), but I chickened out and decided to wait until the first resin layer had cured.

While I waited for the resin to settle over the sand and glass, I poured the first layer of resin into two coaster molds and added some metallic flakes and later some blue alcohol ink tinted resin drops as well.

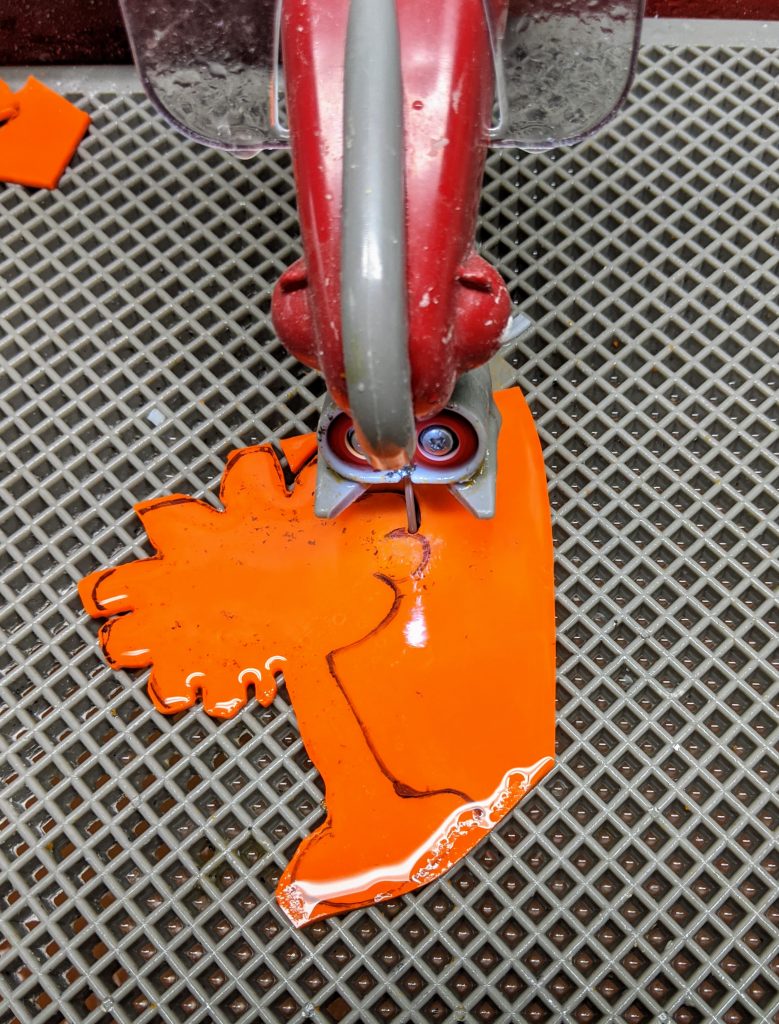

I ordered some bangle bracelet molds the other day and I’m hoping to use a mix similar to the one I used in these coaster molds in those, so I thought I’d try it out with my leftover resin today. I have no idea how it will turn out, but I think I will add another layer with more ink when I mix my next batch of resin for my art-glass-layered-wave-beach panel. I poured and spread the resin as needed, used my small craft stick to remove bubbles and then used the heat gun on all three items to further remove bubbles. While I waited for the resin to settle (you have to hang out for 30-60 minutes and watch for more bubbles in case they decide to pop up), I cut out two more palmetto and crescents using my glass saw; one set orange and one white.

Tomorrow I will add the second wave layer over the sand / beach on the glass panel and hopefully layers for the orange / white palmetto and crescent glass panel and another tinted layer for the coaster experiment.

The resin cured on both of these overnight. Even though the wave project didn’t go completely as planned, I am pleased with it. It looks amazing when I hold it up to a sunlit window!

Today I needed to coat the edges of the canvas with resin and add another wave to the beach glass piece. I think I should have started the first wave on the beach up on the sand, so I tried adding one there at the same time as adding a second wave. I mixed 40 ml of resin and held back about 10cc for white for the waves.

Things got a bit out of hand for both of these. I smeared a bit too much resin on the top of the canvas. I should have just used some rubbing alcohol to remove it, but instead I tried coating the whole thing, but I didn’t have enough resin left to fully coat it. I ended up mixing another 40ml to help coat it. Hopefully it will turn out OK, though I’m mad at myself because it was really smooth before I did this. I also think I poured a bit too much of the white pigmented resin on the beach glass. I was hoping for a bit more separation between the waves. However, this is the first piece I’ve tried to make layered waves on so far, so it is a learning process.

In the end, I think it will be ok, just not exactly what I had planned. I decided to add a starfish while I was at it.

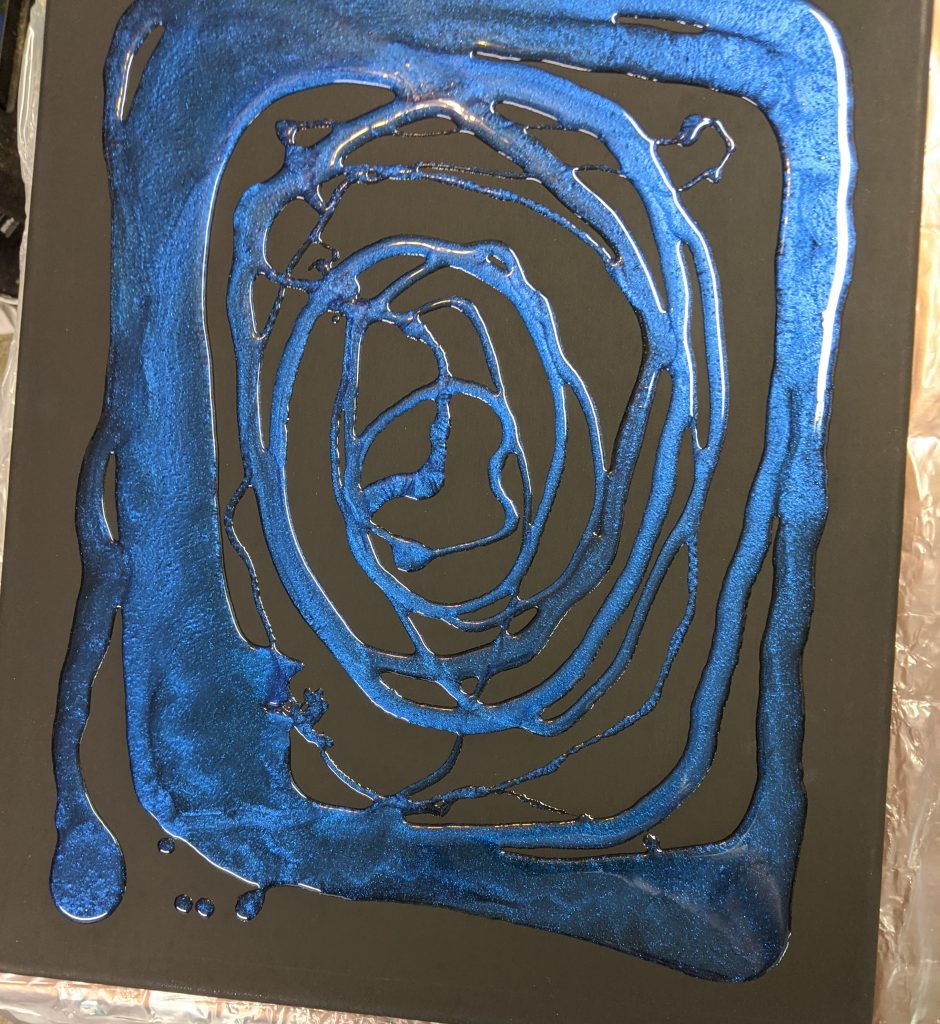

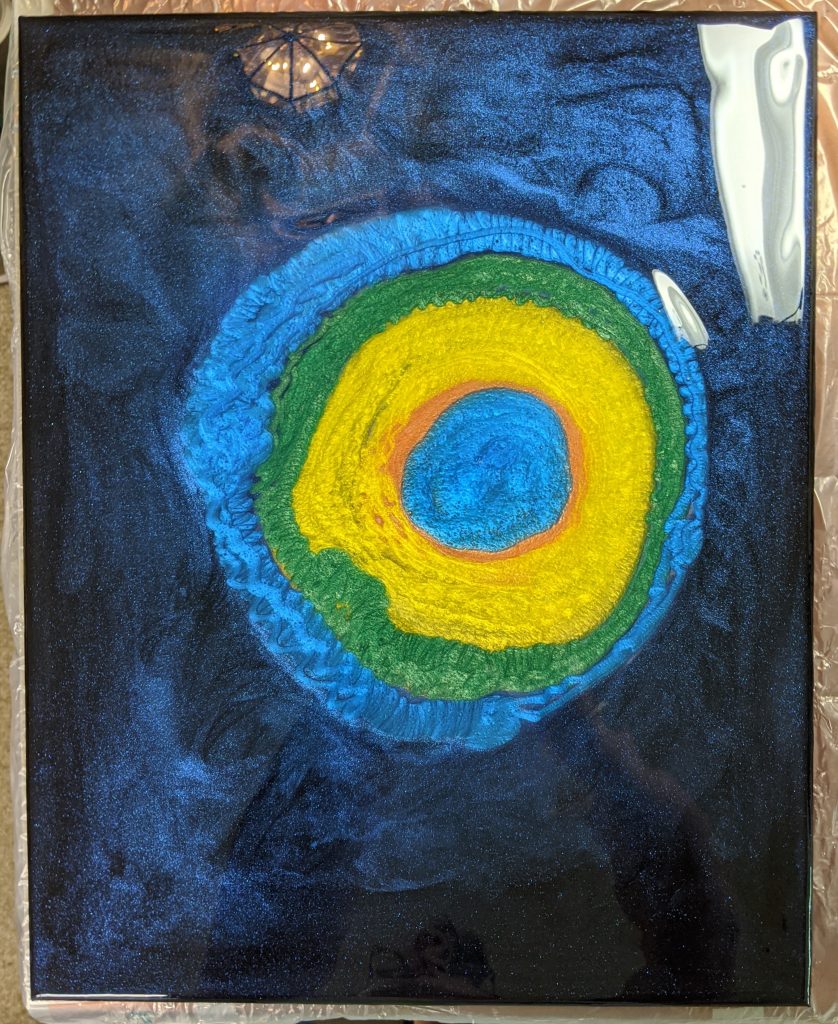

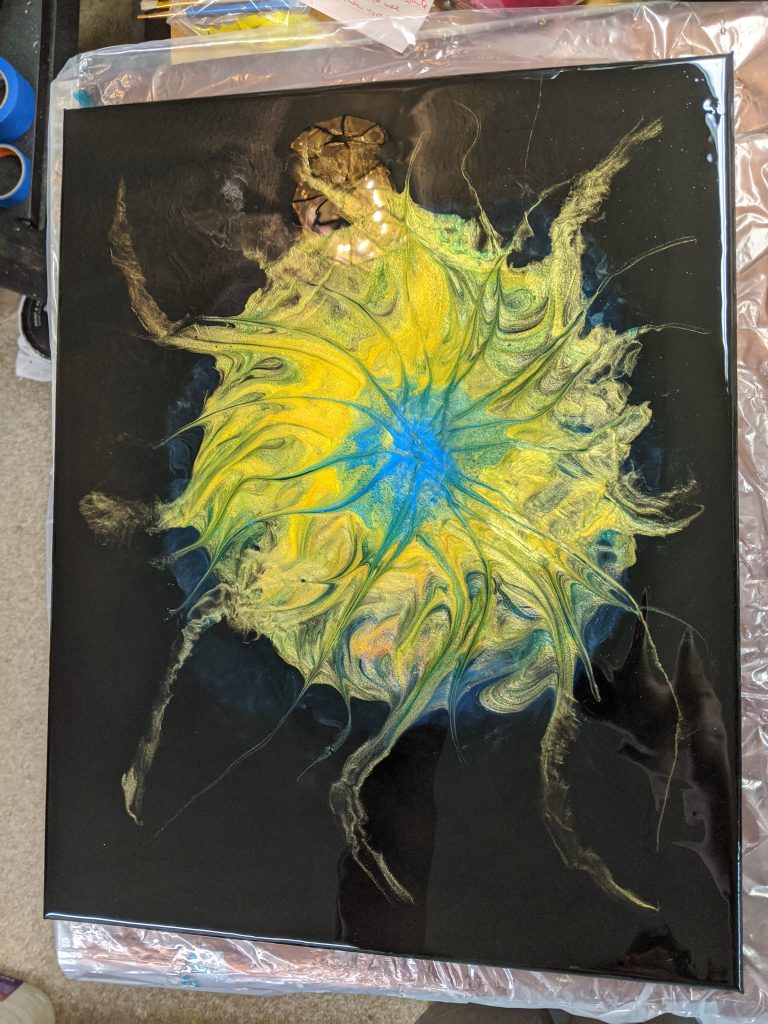

Today I added the first “wave” on top of the initial cured layer of resin over glass and embarked upon my second attempt at a design on canvas with pigmented resin.

I laid out the vessels and pigments I planned to use for the resin. The pigment I used for the canvas background was the powdered Natural Blue (not pictured below). I added a drop or two of the liquid pigments to some of the powdered mix, as well. The green also got some additional yellow powdered pigment because it just looks too blue without it. All of those pigments were for the canvas, I only used a small amount of powdered white pigment with a drop of liquid white for the glass project.

After mixing 400 ml of resin and separating it into cups, I started with the glass panel. I had to spread a thin coat of clear resin over the glass (not the sand, which I think I made too thick…will try a thinner layer next time). After I used the heat gun to remove bubbles, I added a thin line of the white tinted resin to the very edge of the sand on top of the clear layer of resin I had just spread. Once it was in place, I spread it a bit with the heat gun, then quickly hit it with a blast from the butane kitchen torch to spread it like the seafoam that flows when the waves crash against the beach.

Next I turned my attention to the canvas and spread the blue background coating of resin all over it with a sponge on a stick.

I then blew it with the heat gun to smooth / remove bubbles. It really evened out the look. On my first canvas, I didn’t have enough resin for a thick enough coat, but this one had just the right amount, I think. I then added the colors in circles / layers in the middle of the canvas and blew it with the heat gun again. I also really love the way the blue background turned out this time. The powdered pigment looked just how I wanted it to look.

Since I’m just a beginner with this, I am still figuring out how much I want to manipulate the resin with the gun / torch. I think that the canvas projects are too large to do with other projects at the same time, as the resin was getting a bit too thick before I was done manipulating it this time.

I used a craft stick to add the wiggles to the design and combine the colors together, then used the heat gun and torch to move things a bit more. After that, I used a craft stick to reduce the drips around the edges of the canvas. I plan on added in thin coat of clear resin to the edges in a day or two when I go back to add another wave layer to the glass beach project. I also mixed up a small amount of Glint Bronze powdered pigment to add to the center of the design, as I wasn’t satisfied with the look in the center.

I didn’t pour quite enough resin on the canvas I made the other day, so I wanted to add a thin layer on the top of it and also pour the first layer on my new beach / layered wave project. First I propped up my glass on which I applied the sandy beach yesterday so it would be ready for the resin.

I probably should have taped the underside of the glass, but I didn’t think of it until it was too late, so I had to scrape the drips off before the resin cured.

I’m not sure I will get the desired outcome with the canvas, but it’s my first one so I’m still on the steep learning curve. I might need to make a cardboard or foam support that fits the inside of these frames for better support.

I wasn’t able to remove all the bubbles / irregularities in this coat, so I will see how bad it is tomorrow.

I’ve got so many project ideas I want to try that it seems like I’m doing something new each day. Right now I have the canvas I started the other day that needs a finishing coat of clear resin, and I started a new glass / beachy project. For this panel, I started with a pretty sheet of glass that reminded me of the ocean. After cutting the glass to a manageable size and grinding the edges, the first step was to add some sand for the beach. I used real sand and mosaic adhesive.

The down side of this project is it is going to take several days to complete, as I can’t pour any resin until the adhesive on the sand dries completely. My plan for the waves is to do one wave per day. Sigh. At least I will be able to finish the canvas I started the other day and then start on a new canvas when I’m working on the layers for the waves.